Adresa:

No.233-3 Yangchenghu Road, Xixiashu Industrial Park, Xinbei District, Changzhou City, Jiangsu Province

• Visoka preciznost i visoka učinkovitost mogu postići visokokvalitetnu obradu površine bakrenih elektroda.

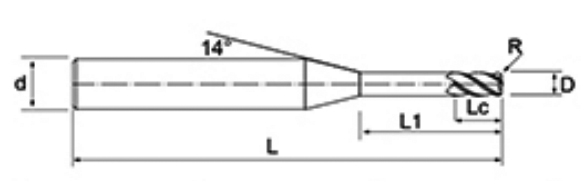

| br. | Promjer D | R kut R | Duljina flaute Lc | Efektivna duljina L1 | Ukupna duljina L | Dia drške d | Broj oštrica F |

| NNX-4RSP-D1-L4 | 1 | 0.1 | 1.5 | 4 | 50 | 4 | 2 |

| NNX-4RSP-D1-L6 | 1 | 0.1 | 1.5 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D1-L8 | 1 | 0.1 | 1.5 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D1-L10 | 1 | 0.1 | 1.5 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D1-L12 | 1 | 0.1 | 1.5 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D1-L14 | 1 | 0.1 | 1.5 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D1-L16 | 1 | 0.1 | 1.5 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D1-L18 | 1 | 0.1 | 1.5 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D1-L20 | 1 | 0.1 | 1.5 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D1-L4 | 1 | 0.2 | 1.5 | 4 | 50 | 4 | 2 |

| NNX-4RSP-D1-L6 | 1 | 0.2 | 1.5 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D1-L8 | 1 | 0.2 | 1.5 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D1-L10 | 1 | 0.2 | 1.5 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D1-L12 | 1 | 0.2 | 1.5 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D1-L14 | 1 | 0.2 | 1.5 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D1-L16 | 1 | 0.2 | 1.5 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D1-L18 | 1 | 0.2 | 1.5 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D1-L20 | 1 | 0.2 | 1.5 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L6 | 1.5 | 0.1 | 2.3 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L8 | 1.5 | 0.1 | 2.3 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L10 | 1.5 | 0.1 | 2.3 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L12 | 1.5 | 0.1 | 2.3 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L14 | 1.5 | 0.1 | 2.3 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L16 | 1.5 | 0.1 | 2.3 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L18 | 1.5 | 0.1 | 2.3 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L20 | 1.5 | 0.1 | 2.3 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L6 | 1.5 | 0.2 | 2.3 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L8 | 1.5 | 0.2 | 2.3 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L10 | 1.5 | 0.2 | 2.3 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L12 | 1.5 | 0.2 | 2.3 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L14 | 1.5 | 0.2 | 2.3 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L16 | 1.5 | 0.2 | 2.3 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L18 | 1.5 | 0.2 | 2.3 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L20 | 1.5 | 0.2 | 2.3 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D2-L6 | 2 | 0.1 | 3 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D2-L8 | 2 | 0.1 | 3 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D2-L10 | 2 | 0.1 | 3 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D2-L12 | 2 | 0.1 | 3 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D2-L14 | 2 | 0.1 | 3 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D2-L16 | 2 | 0.1 | 3 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D2-L18 | 2 | 0.1 | 3 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D2-L20 | 2 | 0.1 | 3 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D2-L6 | 2 | 0.2 | 3 | 6 | 50 | 4 | 4 |

| NNX-4RSP-D2-L8 | 2 | 0.2 | 3 | 8 | 50 | 4 | 4 |

| NNX-4RSP-D2-L10 | 2 | 0.2 | 3 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D2-L12 | 2 | 0.2 | 3 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D2-L14 | 2 | 0.2 | 3 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D2-L16 | 2 | 0.2 | 3 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D2-L18 | 2 | 0.2 | 3 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D2-L20 | 2 | 0.2 | 3 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D2-L6 | 2 | 0.5 | 3 | 6 | 50 | 4 | 4 |

| NNX-4RSP-D2-L8 | 2 | 0.5 | 3 | 8 | 50 | 4 | 4 |

| NNX-4RSP-D2-L10 | 2 | 0.5 | 3 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D2-L12 | 2 | 0.5 | 3 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D2-L14 | 2 | 0.5 | 3 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D2-L16 | 2 | 0.5 | 3 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D2-L18 | 2 | 0.5 | 3 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D2-L20 | 2 | 0.5 | 3 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D3-L10 | 3 | 0.1 | 4.5 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.1 | 4.5 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.1 | 4.5 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.1 | 4.5 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.1 | 4.5 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.1 | 4.5 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D3-L10 | 3 | 0.2 | 4.5 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.2 | 4.5 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.2 | 4.5 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.2 | 4.5 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.2 | 4.5 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.2 | 4.5 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D3-L10 | 3 | 0.5 | 4.5 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.5 | 4.5 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.5 | 4.5 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.5 | 4.5 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.5 | 4.5 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.5 | 4.5 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.2 | 4.5 | 12 | 60 | 6 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.2 | 4.5 | 14 | 60 | 6 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.2 | 4.5 | 16 | 60 | 6 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.2 | 4.5 | 18 | 60 | 6 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.2 | 4.5 | 20 | 60 | 6 | 4 |

| NNX-4RSP-D3-L25 | 3 | 0.2 | 4.5 | 25 | 60 | 6 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.5 | 4.5 | 12 | 60 | 6 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.5 | 4.5 | 14 | 60 | 6 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.5 | 4.5 | 16 | 60 | 6 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.5 | 4.5 | 18 | 60 | 6 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.5 | 4.5 | 20 | 60 | 6 | 4 |

| NNX-4RSP-D3-L25 | 3 | 0.5 | 4.5 | 25 | 60 | 6 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.2 | 4.5 | 12 | 75 | 6 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.2 | 4.5 | 14 | 75 | 6 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.2 | 4.5 | 16 | 75 | 6 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.2 | 4.5 | 18 | 75 | 6 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.2 | 4.5 | 20 | 75 | 6 | 4 |

| NNX-4RSP-D3-L25 | 3 | 0.2 | 4.5 | 25 | 75 | 6 | 4 |

| NNX-4RSP-D3-L30 | 3 | 0.2 | 4.5 | 30 | 75 | 6 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.5 | 4.5 | 12 | 75 | 6 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.5 | 4.5 | 14 | 75 | 6 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.5 | 4.5 | 16 | 75 | 6 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.5 | 4.5 | 18 | 75 | 6 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.5 | 4.5 | 20 | 75 | 6 | 4 |

| NNX-4RSP-D3-L25 | 3 | 0.5 | 4.5 | 25 | 75 | 6 | 4 |

| NNX-4RSP-D3-L30 | 3 | 0.5 | 4.5 | 30 | 75 | 6 | 4 |

| NNX-4RSP-D4-L16 | 4 | 0.2 | 6 | 16 | 60 | 6 | 4 |

| NNX-4RSP-D4-L20 | 4 | 0.2 | 6 | 20 | 60 | 6 | 4 |

| NNX-4RSP-D4-L25 | 4 | 0.2 | 6 | 25 | 60 | 6 | 4 |

| NNX-4RSP-D4-L16 | 4 | 05 | 6 | 16 | 60 | 6 | 4 |

| NNX-4RSP-D4-L20 | 4 | 0.5 | 6 | 20 | 60 | 6 | 4 |

| NNX-4RSP-D4-L25 | 4 | 0.5 | 6 | 25 | 60 | 6 | 4 |

| NNX-4RSP-D4-L16 | 4 | 0.2 | 6 | 16 | 75 | 6 | 4 |

| NNX-4RSP-D4-L20 | 4 | 0.2 | 6 | 20 | 75 | 6 | 4 |

| NNX-4RSP-D4-L25 | 4 | 0.2 | 6 | 25 | 75 | 6 | 4 |

| NNX-4RSP-D4-L30 | 4 | 0.2 | 6 | 30 | 75 | 6 | 4 |

| NNX-4RSP-D4-L35 | 4 | 0.2 | 6 | 35 | 75 | 6 | 4 |

| NNX-4RSP-D4-L16 | 4 | 0.5 | 6 | 16 | 75 | 6 | 4 |

| NNX-4RSP-D4-L20 | 4 | 0.5 | 6 | 20 | 75 | 6 | 4 |

| NNX-4RSP-D4-L25 | 4 | 0.5 | 6 | 25 | 75 | 6 | 4 |

| NNX-4RSP-D4-L30 | 4 | 0.5 | 6 | 30 | 75 | 6 | 4 |

| NNX-4RSP-D4-L35 | 4 | 0.5 | 6 | 35 | 75 | 6 | 4 |

| Serija alata | Promjer | Radijus | Polumjer kuta | Duljina svirale | Efektivna duljina | Ukupna duljina | Dia drške | |||

| D | R | CR | Lc | L1 | L | d | ||||

| NNX glodala od tvrdog metala za bakrene elektrode | D0.1~D0.9 | 0 -0,005 | R0,05~R2 | /-0,005 | CR0,05~CR0,5 | /-0,005 | 0 0.3 | 0 0.3 | 0.5 -0,5 | h5 |

| D1~D3.5 | 0 -0,005 | |||||||||

| D4~D10 | -0,003 -0,015 | R3~R5 | /-0,005 | CR1.0~CR3.0 | /-0,008 | 0 0.5 | 0 0.5 | |||

| D12~D20 | -0,003 -0,018 | R6~R10 | /-0,008 | |||||||

NNX-4RSP glodala s 4 žlijeba i okruglim vrhom s dubokim utorima za obradu bakrenih elektroda nude širok raspon mogućnosti veličine, od malog promjera do velikog promjera, od kratke duljine do duge duljine ruba, svaka specifikacija je pažljivo dizajnirana kako bi zadovoljila potrebe različitih radnih uvjeta. Bilo da se radi o finoj obradi ili rezanju velike površine, fleksibilna kombinacija različitih podmodela omogućuje korisnicima da slobodno izaberu najprikladniji alat za postizanje učinkovite i točne obrade bakrene elektrode.

Specijalni dizajn okruglog vrha s dubokim utorima ne samo da povećava krutost alata, već i optimizira raspodjelu sile oštrice, učinkovito smanjujući vibracije i neravnine tijekom obrade. Jedinstveni dizajn utora smanjuje otpor rezanja, osigurava stabilno rezanje materijala bakrene elektrode pri velikim brzinama i poboljšava završnu obradu površine.

Alat koristi supstrat s ultra finim česticama (0,2 μm) s najnovijom tehnologijom DLC premaza, koji ima izvrsnu otpornost na habanje i iznimno nizak koeficijent trenja, što ga čini posebno superiornim u obradi bakrene elektrode. U kombinaciji s tehnologijom ultra-finog brušenja i oštricom ultra-niske hrapavosti, uvelike smanjuje problem prianjanja alata i poboljšava vijek trajanja i dosljednost obrade.

Osnivanje poduzeća

Zaposlenici

Changzhou Maton Tools Co.,Ltd. is located in the economically developed Yangtze River Delta region.The factory is located in XixiashuHigh-tech Development Zone,a well-known tool town in China. We are Čeono glodalo s dubokim žlijebom i okruglim vrhom za obradu bakrenom elektrodom Suppliers.

Magotantools take the ISO9001 quality system as the standard,under the guidanceof the business philosophy of"zero defect in products"and"zero distance in service",based on the spirit of"integrity","unity"and"exploita- tion",and follow a fair and just company style for management.Product production adopts five-axisand six-axis CNC grinding and machining centers from Germany,Switzerland,Japan,etc.,and is equipped with high-precision testing equipment such as Germany,Japan,and China,so as to meet the needs of production with high quality and quantity.

The company continuously develops various high-performance CNC tools, and has won various national awards. Professional Čeono glodalo s dubokim žlijebom i okruglim vrhom za obradu bakrenom elektrodom Factory. More than 10 patents,the company's products are mainly used in the defense industry, aerospace industry,automotive industry,electronic products and molds and other fields.

The company's various products are recognized and favored by well-known domestic companies.With infinite technology,infinite creation,and pursuit of excellence,Magotan tools will write future prosperity and dreams with more extraordinary confidence and high-quality quality.

Odgovorit ćemo vam unutar 12 sati nakon primitka upita radnim danom.

Mi smo proizvođači, sami proizvodimo i prodajemo.

We mainly produce tungsten steel milling cutters, drill bits and other hard alloy tools. Professional Čeono glodalo s dubokim žlijebom i okruglim vrhom za obradu bakrenom elektrodom Suppliers.

Naši proizvodi pokrivaju gotovo cijelu industriju kalupa, obrambenu industriju, zrakoplovnu industriju, automobilsku industriju, elektroničke proizvode i druga područja.

Yes, our main focus is on customized products. We develop and produce products based on the drawings or samples provided by customers. Custom Čeono glodalo s dubokim žlijebom i okruglim vrhom za obradu bakrenom elektrodom.

We have over 30 units of WALTER from Germany, Makino from Japan, ROLLMATIC from Switzerland, and TTB from Switzerland, with an annual output value of 80 million RMB. We are Čeono glodalo s dubokim žlijebom i okruglim vrhom za obradu bakrenom elektrodom Factory

Prvo, nakon svakog procesa provodimo odgovarajuće inspekcije. Za konačni proizvod, mi ćemo provesti 100% punu inspekciju u skladu sa zahtjevima kupaca i međunarodnim standardima;

Zatim, imamo naprednu i kompletnu vrhunsku opremu za testiranje u industriji, kao što su spektralni analizatori, metalografski mikroskopi itd., koji mogu osigurati stabilnost i konzistentnost reznih alata, dok istovremeno ispunjavaju zahtjeve kupaca za visokoprecizno testiranje reznih alata.

Prilikom ponude, potvrdit ćemo s vama način transakcije, FOB, CIF, CNF ili druge opcije. Kod masovne proizvodnje obično prvo plaćamo 30% avansa, a zatim plaćamo ostatak uz predočenje teretnice. Uglavnom koristimo T/T kao način plaćanja, ali L/C je također prihvatljiv.